Looking forward and adapting the latest technologies is important for innovation within the company. Staying ahead is anticipating on the coming changes of supply & demand within the global market. We proudly present the new acquisitions within Larsen & Buhl.

The Makino D500 has recently been added to our production facility of 5000m2. This high tech milling machine is known as very reliable and is able to deliver high precision and complex 5-axis milling work. The D500 can perform exactly one thousandth of a millimetre. As a result we can meet even more the current and new customer’s requirements.

In addition to the investment in the Makino, a number of other investments have been made, including the DMG DMU 40 EVO fully automated with the Erowa Multi palletizing system.

This machine is very suitable for small precision work and will support, among other things, production in the medical sector. Because the DMU operates very consistently and in series, and also has a high work rate, this machine is also an excellent addition to our state-of-the-art production technology!

Larsen & Buhl shaping the future with precision

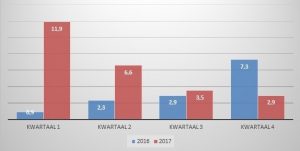

Increase in turnover 2017 in the metal industry

Metalkrant.nl recently published an interesting article about turnover figures in the metal industry. The sector in the metal industry is growing and Larsen & Buhl is also growing in this. Overall the sector in the metal increased by 13.6% in 2017 compared to 2016, according to figures from the Central Statistical Office. Pictured in the graph above.

Metalkrant.nl recently published an interesting article about turnover figures in the metal industry. The sector in the metal industry is growing and Larsen & Buhl is also growing in this. Overall the sector in the metal increased by 13.6% in 2017 compared to 2016, according to figures from the Central Statistical Office. Pictured in the graph above.

Larsen & Buhl shaping the future with precision